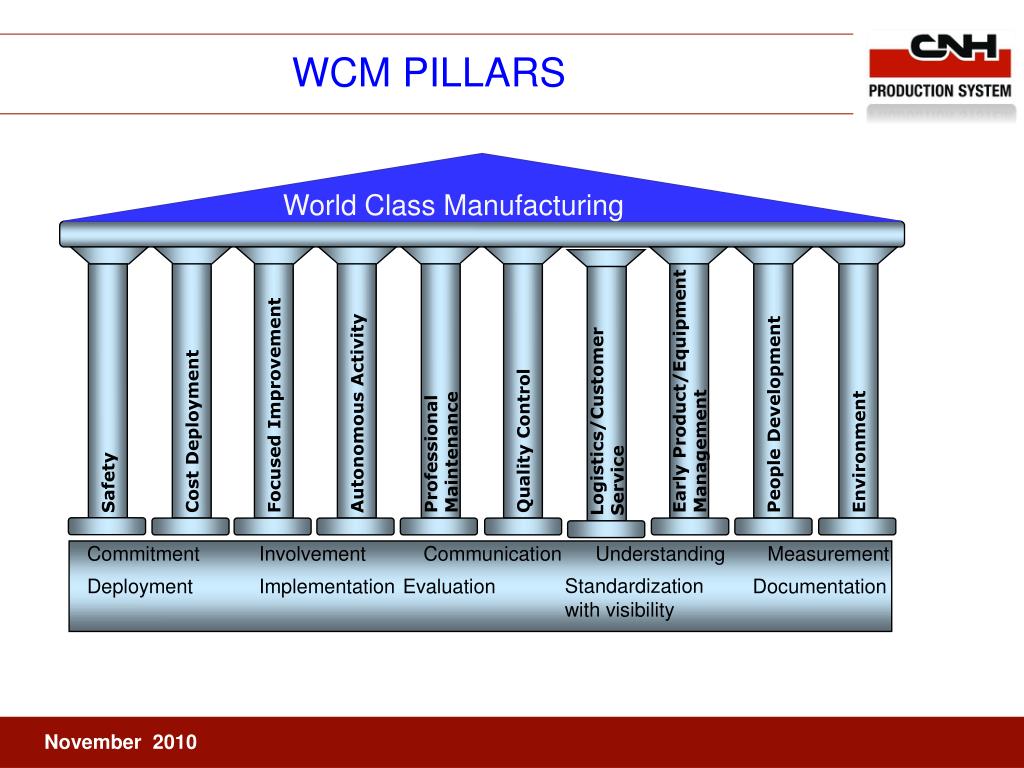

world class manufacturing pillars

30 of these are Chrysler plants whereas 45 belong to Fiat. Operations and Manufacturing Planning.

Pillars Description And Features Open Textbooks For Hong Kong

Today 166 manufacturing plants in 16 countries are active partners in the worldwide WCM Association.

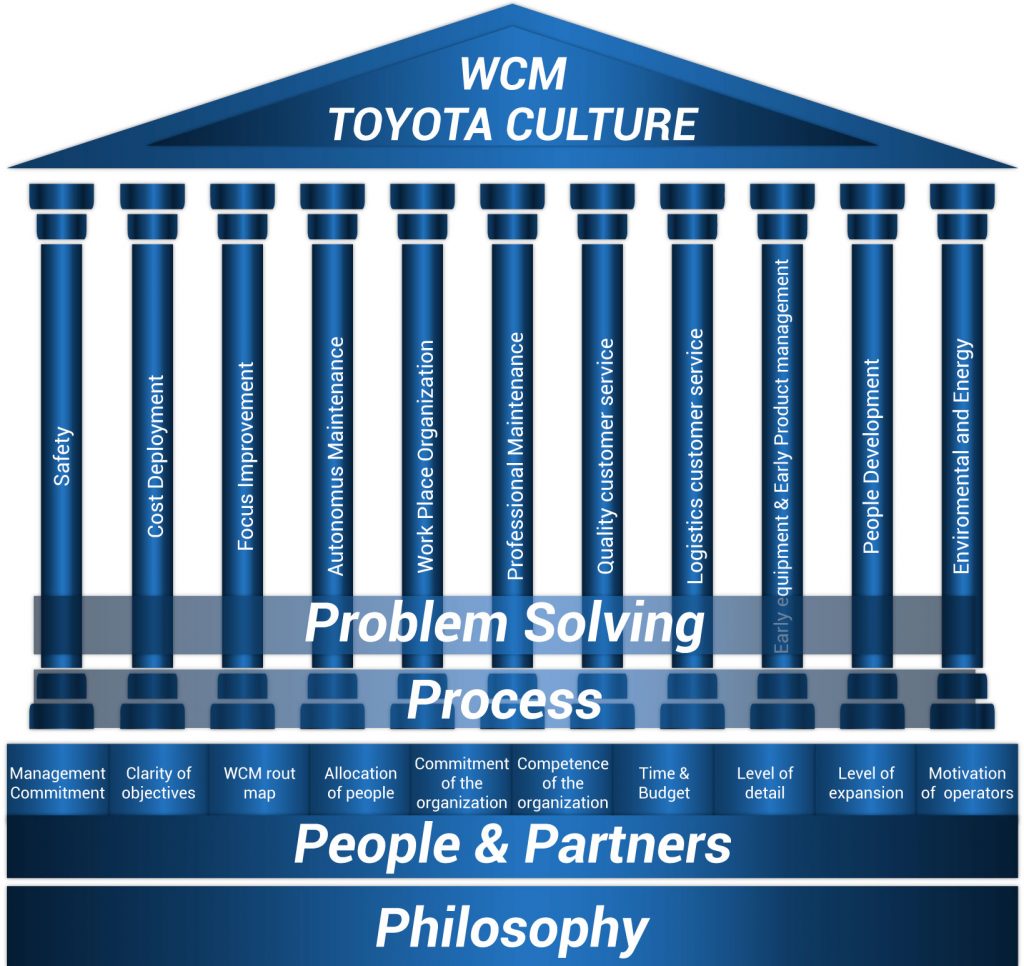

. 7 Time and Budget. 6 Competence of Organization towards Improvement. The ten technical pillars are as follows.

3 - Established and efficient reliability and maintenance programs. WCM World Class Manufacturing is a set of management principles and techniques. Global quality through World Class Manufacturing.

Implementation of total quality management leads to reduction of defects and encourages zero tolerance towards defects. The involvement of people is the key to change. There are seven keys to becoming a world-class manufacturer.

The content of World Class Manufacturing. It is not just a project but a new way of working accident prevention is a non-derogated value. 3 Route map to WCM.

This pillar is why most manufacturing facilities fall short. 6 days ago The 10 technicalpillars of World Class Manufacturing are. Deployment where are the losses.

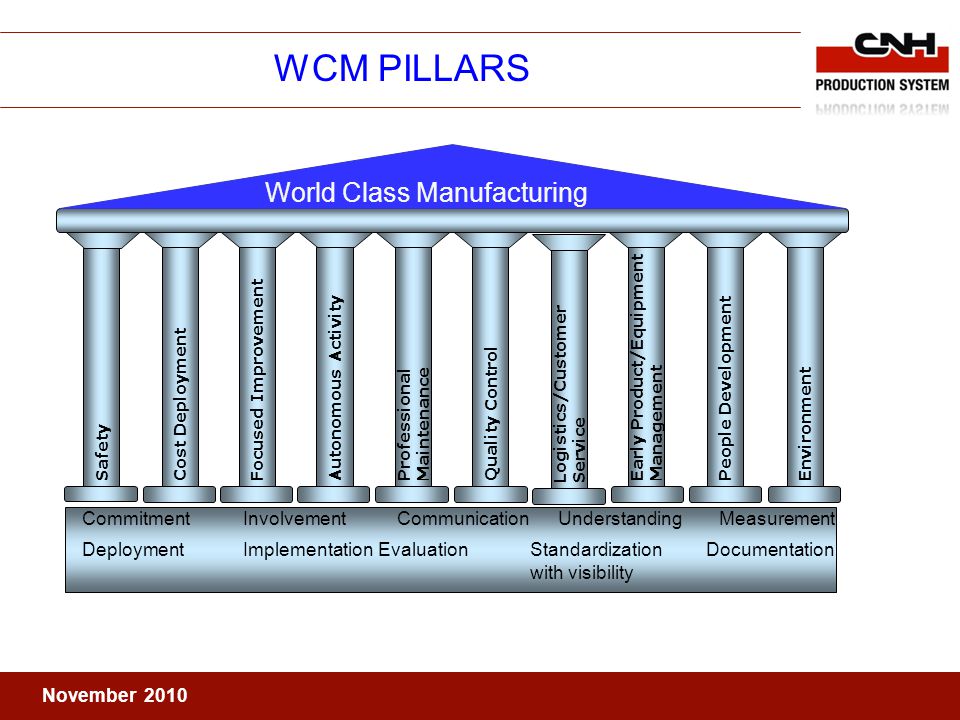

And the ten managerial pillars are. Teams Increase efficiency productivity Reduction of waste Reduction of complaints and claims Increase Safety Motivation. The customers voice should reach all departments and offices.

Establishment of maintenance standards. WCM aims to ensure that the FCA Groups facilities are flexible and competitive with the best in the world. The 10 managerial pillars of World Class.

Communications Improving Performance Visibility. President of the consulting firm of Schonberger Associates Inc in Seattle Washington he was formerly George Cook Professor of Management at the University of Nebraska. If this sounds familiar its because WCM shares countless similarities with Lean philosophy.

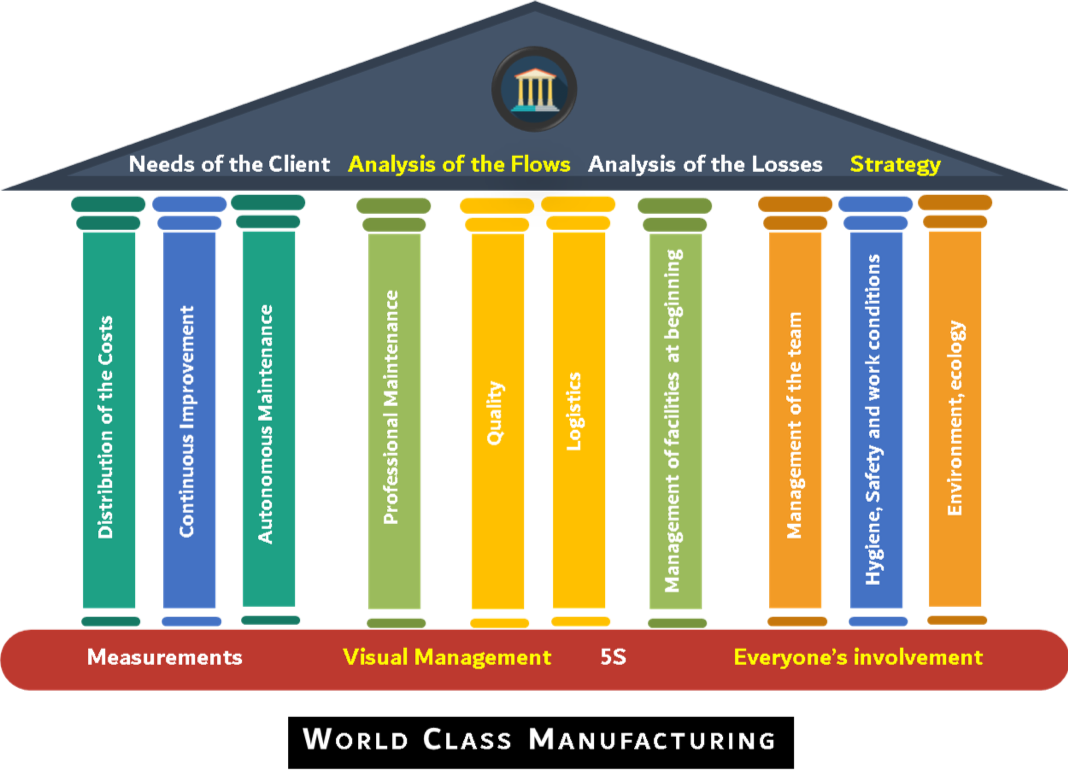

Elimination of forced deterioration and prevention of accelerated deterioration. Autonomous maintenance and workplace organization 5. Thus World Class Manufacturing is based on a few fundamental principles.

Resources are focused on reducing breakdowns improving quality improving customer satisfaction and improving productivity. At CNH Industrial the use of tools for sharing information and collecting suggestions is well established. Many focus areas are considered as part of the continuous improvement process.

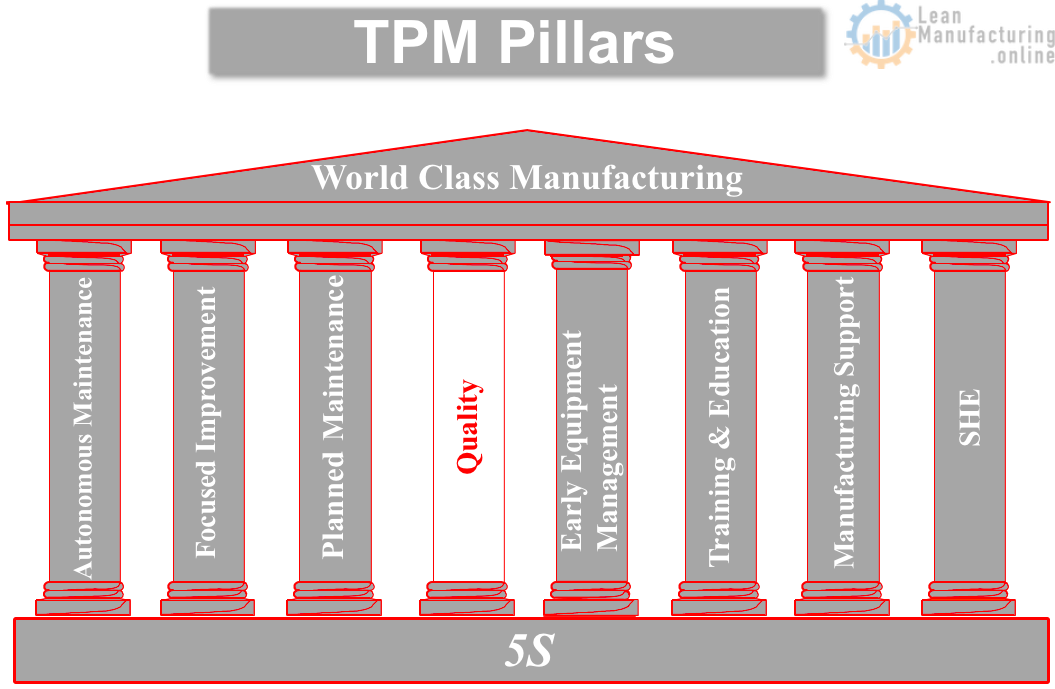

There are three main principles which drive world-class manufacturing. WORLD CLASS MANUFACTURING 3 6 Constant innovation in the products and services you provide. The WCM system is made up of ten technical- and ten managerial pillars illustrated as a temple see below.

The pillars of World Class Manufacturing. The implementation and management of WCM involves continuously capturing and analysing data tracking reporting and counteracting losses and directing initiatives for continuous improvement of production processes. World Class Manufacturing WCM is a comprehensive management system designed to improve business performance through loss elimination.

1 Management Commitment 2 Clarity of Objectives 3 Route map to WCM 4 Allocation of Highly Qualified People to Model Areas 5 Commitment of the Organization. Providing seamless synchronization throughout the value chain so that you have a line of sight from the moment you have contact from a customer. In the mid-1980s when Toyota increasingly.

Autonomous maintenance and workplace organization. In 2014 14277 projects were implemented within WCM generating savings of 1956 million. Methodologies and tools 5S 4M 5 Why ECRS.

9 Expansion Level and 10 Motivation of Operators. World class manufacturing - CEOpedia Management. Definitions The Toyota Way can be briefly summarized through the two pillars that support it.

Reverse deterioration Breakdown Analysis Step 3. 2 Clarity of Objectives. Schonberger author of Japanese Manufacturing Techniques also from The Free Press is a world-renowned authority on production and manufacturing.

You have to be first to market and provide end-to-end solutions. Countermeasures against weak points of the machine and lengthened equipment life. The 10 technical pillars of World Class Manufacturing are.

Definition of World Class Manufacturing. Download scientific diagram World Class Manufacturing pillars from publication. Principles of World Class Manufacturing.

Reliability culture is the most elusive and most important pillar to achieve World Class reliability. Knowledge Management and World Class Manufacturing. The ten pillars of World Class Manufacturing.

An initial approach based on a. Logistics. In 2014 about 395 thousand suggestions were collected across the plants where WCM principles are applied with an average of 11 per employee.

All leaders must demand respect for the standards set. As regards the ten Managerial Pillars there are. WCM professionals thus have the responsibility of coordinating the design execution.

February 11 2022. 4 Allocation of Highly Qualified People to Model Areas. Implementation of just in time and lean management leads to reduction in wastage thereby reduction in cost.

7 steps of PM. Sergio Marchionne CEO of Fiat Chrysler Automobiles NV. Continuous improvement and Respect for people Lean Manufacturing also called Toyota Production System TPS is a production system inspired by the Japanese concept of kaizen the strategy.

Based on some pillars that will be presented later this methodology focuses on best practices for management with zero-waste.

Oem Wcm World Class Manufacturing Alfra Lean Advisors

6s A Solid Rock In World Class Manufacturing

Wcm Pillars Description And Features Business Building Information

10 Steps To Achieve World Class Manufacturing Maintenance Practices M A N O X B L O G

10 Pillars Of World Class Manufacturing Visit Us For 100 Operational Excellence Presentation U Nikunjbhoraniya

The World Class Manufacturing Programme At Chrysler Fiat Co Better Operations

World Class Manufacturing Wcm Model And Operational Performance Indicators Comparison Between Wcm Firms Semantic Scholar

Eight Pillars Of Total Productive Maintenance 5s Foundation World Class Manufacturing Roof Quality Continuously Improving Manufacturing

World Class Manufacturing Or Wcm What Is It

World Class Manufacturing Pillars Download Scientific Diagram

Robert Becklin Operations Supervisor Emerson Linkedin

Quality Maintenance An Essential Pillar For World Class Manufacturing

November 2010 Wcm Pillars World Class Manufacturing Cost Deployment Autonomous Activity Professionalmaintenancequality Controllogistics Customerserviceearly Ppt Download

World Class Manufacturing Or Wcm What Is It

Illustrates The Ten Pillars Of Wcm Download Scientific Diagram

Ppt Wcm Pillars Powerpoint Presentation Free Download Id 574411